Freezing vs. refrigeration: The battle for crop preservation in the global export trade - which is right for your agricultural commodity?

- Al Hawam

- Apr 26

- 4 min read

In the era of agricultural globalization, cryopreservation and freezing techniques are essential to ensure that agricultural products reach global markets with high quality. But choosing the right method depends on the nature of the crop, transportation conditions, and the requirements of the target market. What is the scientific and practical difference between them, and how does this difference affect export strategies?

1.Scientific Basis: Why do memorization methods differ?

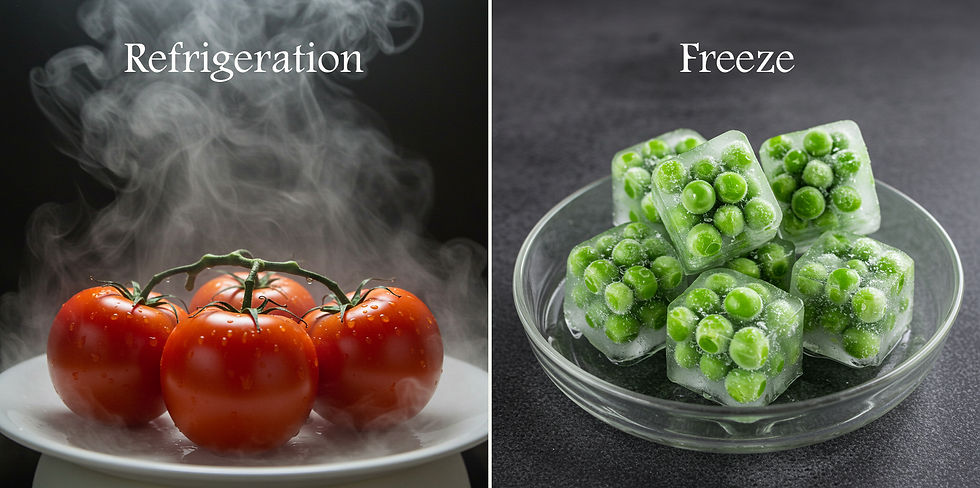

- Freezing:

Temp: Below -18°C, which completely inactivates enzymes and microbes.

Impact on cells: The formation of ice crystals may damage the cell walls of wet crops (e.g. strawberries), changing their texture after thawing.

Suitable crops: Thick-skinned fruits (berries, mangoes), hard vegetables (corn, peas), and processed products (French fries).

- Refrigeration:

Temperature: 0°C to 5°C, slows down chemical and biological reactions without freezing.

Effect on cells: Preserves the normal structure of tissues, but does not completely stop damage.

Suitable crops: Leafy vegetables (spinach, lettuce), delicate fruits (bananas, avocados), and fresh produce that loses its value by freezing (tomatoes, citrus fruits).

2. Export and long-distance transportation: Challenges and solutions

A- Freezing:

- Advantages:

Longer shelf life (up to 12 months), allowing for less frequent shipments.

Logistical flexibility: Possibility of using slow (less expensive) sea transportation.

- Challenges:

High energy costs: Need for super-cooled refrigerated containers.

Texture changes: May require reprocessing after thawing (e.g. use in smoothies instead of selling fresh).

B- Refrigeration:

- Advantages:

Preserves the “fresh” nature of the product, increasing its marketing value.

Lower operating costs compared to freezing.

- Challenges:

Short shelf life (days to weeks), requiring fast supply chains.

Sensitivity to temperature fluctuations: Any disruption in the cold chain leads to rapid spoilage.

Customized refrigerated container for transporting heat-sensitive products during shipping.

3.Case studies from the Egyptian market: How does Egypt benefit from freezing and refrigeration in exports?

-Freezing: Successful Egyptian examples

Egyptian sweet corn to the European Union:

- Product: Frozen sweet corn.

- Region: Grown in the Delta and Nile Valley, processed in freezing plants in cities such as Sixth of October.

- Processes: Corn is harvested at peak ripeness, then quickly blanched and frozen with Individual Quick Freezing (IQF) technology to preserve the natural sugars.

- Export: Shipped via Alexandria Port in refrigerated containers (-18°C) to countries such as Germany and the Netherlands.

- Reason: To avoid quality loss during the 10-14 day sea voyage.

- Economic impact: Egypt is one of the top 5 exporters of frozen corn globally, with annual revenues exceeding $120 million.

Egyptian strawberries to Gulf countries:

- Product: Frozen strawberries.

- Region: Cultivated in Beheira and Menoufia governorates.

- Processes: Strawberries are frozen within hours of harvest using liquid nitrogen to prevent the formation of ice crystals that affect the texture.

- Export: They are transported by air or sea to Saudi Arabia and the UAE, where they are used in juices and desserts.

- Reason: Fresh strawberries cannot withstand long road transportation in hot conditions.

- Challenge: The high cost of airfreight, which limits the profit margin.

-Refrigeration: Featured Local Models

Egyptian mangoes to the European Union:

- Product: Chilled fresh mangoes.

- Region: Grown in Ismailia and Sharqiya.

- Processes: Chilled immediately after harvest to 10°C (optimal temperature for mangoes), then transported in refrigerated trucks to Damietta Port.

- Export: Shipped by sea to Italy and France within 7 days, with humidity monitored to prevent mold.

- Reason: To preserve the distinctive flavor that makes Egyptian mangoes competitive with Indian ones in European markets.

- Economic impact: Mango exports reached USD 65 mn in 2023, up 20% from the previous year.

Egyptian grapes to Russia: - Product: Red and black table grapes.

- Region: New Valley and Giza farms.

- Processes: Pre-cooling is used immediately after harvest to lower the temperature of the grapes to 0°C, then packed in crates with dry ice bags.

- Export: Transported by road through Turkey to Russia within 5 days.

-Reason: Grapes are highly sensitive to high temperatures, making them susceptible to rapid spoilage.

-Challenge: Stiff competition with Turkish grapes in the Russian market.

4. Case studies from the global market:

- Freezing:

Exporting blueberries from Chile to China: Frozen immediately after harvest for a 30-day cruise while preserving antioxidants.

- Refrigeration:

Mexican avocados to the United States: Transported refrigerated at 4°C to ensure controlled ripening during shipment.

Dutch leafy greens to the Gulf: Packed in refrigerated containers with nitrogen injection to slow down respiration.

5. Economic considerations: Which is more profitable?

- Freezing:

Suitable for countries with well-developed infrastructure (equipped ports, stable electricity).

Preferred for crops with high added value after processing (e.g. juices, ready meals).

- Refrigeration:

Best suited for markets that are geographically close or have fast demand (e.g. exporting vegetables from Morocco to Europe by truck).

Requires investment in monitoring technology (temperature and humidity sensors).

Conclusion: The Future of Crop Preservation in Global Trade

With the development of IQF technology and inteligent refrigeration systems, the line between the two methods is becoming less clear. But the final decision depends on a careful understanding of the nature of the crop, consumer expectations, and the country's logistics structure. While freezing ensures that the product reaches the furthest markets, refrigeration maintains the "aura of freshness" demanded by the luxury market. The ultimate goal? To strike a balance between quality and economic efficiency.

Comentarios